Reference Procedure for Simulating Spandrel U-Factors

A public resource prepared for the Fenestration Association of BC (FENBC) with the financial support of BC Housing under the Building Excellence Research and Education Grants Program

Energy design standards such as ASHRAE 90.1 and the Canadian National Energy Code for Buildings (NECB) require building designers to determine effective U-factors (U-values) for all enclosure assemblies. In these standards, spandrel assemblies utilizing fenestration products are considered to be opaque walls, not fenestration products.

Design standards such as ASHRAE 90.1 and NECB require building designers to determine the effective U-factor of opaque wall assemblies clad with spandrel products. The Reference Procedure for Simulating Spandrel Panel U-Factors was created to allow spandrel U-factor performance claims to be objectively evaluated in a similar way as window U-factor performance claims that are based on NFRC 100 procedures.

Design standards such as ASHRAE 90.1 and NECB require building designers to determine the effective U-factor of opaque wall assemblies clad with spandrel products. The Reference Procedure for Simulating Spandrel Panel U-Factors was created to allow spandrel U-factor performance claims to be objectively evaluated in a similar way as window U-factor performance claims that are based on NFRC 100 procedures.

While various methods are currently employed to determine spandrel U-factors, including physical testing, 2D simulation and 3D thermal modeling, the lack of a “standard” reference methodology makes it difficult for project teams to evaluate or compare performance claims from product suppliers.

As the spandrel products used today often have significantly higher thermal transmittance than fenestration products, use of a recognized reference methodology that produces consistent and comparable results can help project teams to make better-informed choices about spandrel products.

Download the Reference Procedure, User Guide and Calculation Tool

Reference Procedure

The Reference Procedure (RP) is a voluntary procedure that may be used to determine spandrel panel U-factors for whole building energy design standard compliance.

The RP is based on ANSI/NFRC 100-2014 [E0A1] to leverage the availability of existing product simulation data, and the widespread use of industry-standard LBL THERM software by fenestration and spandrel manufacturers. The differences between the RP and this version of NFRC 100 are clearly indicated.

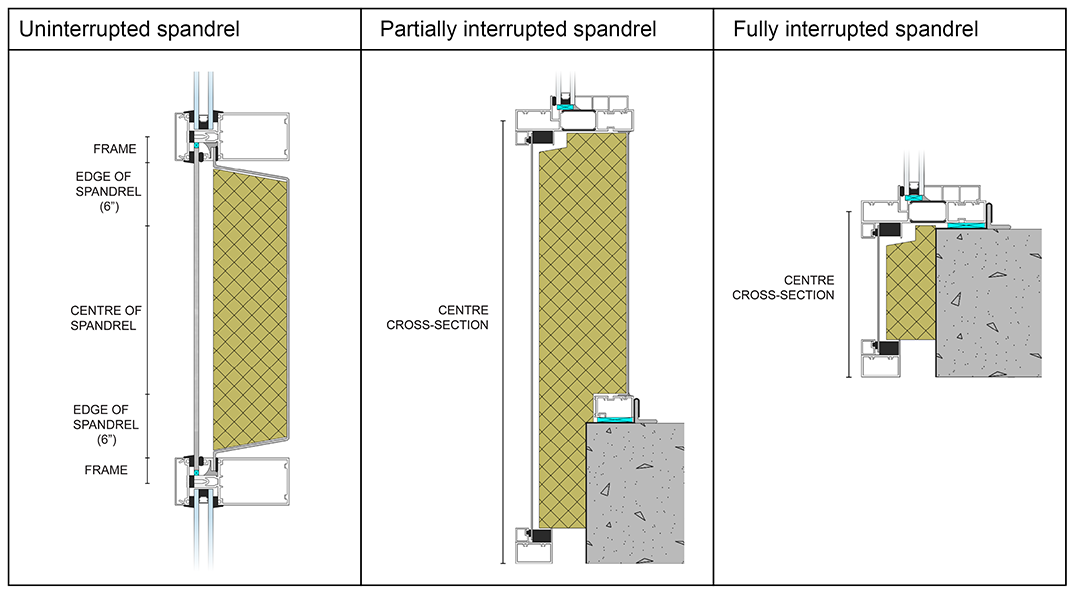

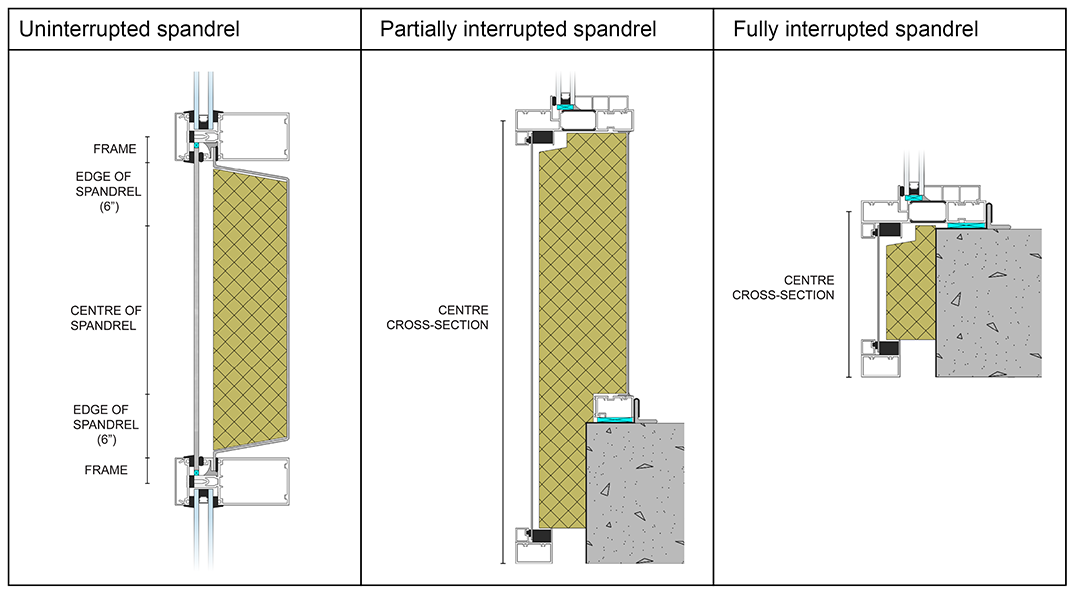

The reference procedure differs from NFRC 100 in three respects:

- The reference procedure increases the panel edge distance from the 63.5 mm (2.5 in.) used for transparent glass to 152.4 mm (6 in.), a dimension found to be more accurate for spandrels.

- The reference procedure offers three spandrel product configurations, one of which is identical to the curtain wall configuration in NFRC 100. The additional configurations address spandrels interrupted by floor slabs.

- The reference procedure utilizes an Excel worksheet to perform area-weighting calculations in place of the LBL WINDOW software.

User Guide

The User Guide provides detailed guidance for using the Reference Procedure with THERM and the Calculation Tool, and is the best place to learn both the overview and the details of using the procedure.

Calculation Tool

The Reference Procedure uses a Microsoft Excel-based calculation tool to perform area-weighted calculations of overall product U-factors. The calculator is designed to accept project-specific or reference-standard product dimensions.

Disclaimer: Every reasonable effort has been made to ensure the accuracy of this tool. However, RDH does not warrant its accuracy and use of the tool is at the user’s discretion. Please notify RDH of bugs or user issues by sending an email to Lorne Ricketts at lricketts@rdh.com.

Reference Procedure FAQ

- Who developed the Reference Procedure, User Guide, and Calculation Tool?

These resources were developed by RDH Building Science Inc. for the Fenestration Association of BC (FENBC) with the participation of the FENBC Technical Committee. The project was completed with the financial support of BC Housing under the Building Excellence Research and Education Grants Program. Visit the BC Housing Research Centre to learn more about the program.

- Why is there a need for a Spandrel U-factor Reference Procedure?

FENBC member companies found there was insufficient guidance in NFRC 100 for simulating spandrels, and particularly the narrow and interrupted spandrels that are common in large buildings today. The lack of a recognized reference methodology was identified as an impediment in evaluating competing performance claims.

The Reference Procedure was created to allow spandrel U-factor performance claims to be determined under uniform conditions to help building designers to objectively evaluate spandrel product performance claims in the same way as they can evaluate window U-factor performance claims based on NFRC 100 procedures.

The Reference Procedure identifies three spandrel conditions that correspond more closely to typical project conditions than the standard reference sizes in NFRC 100 and CSA A440.2, and provides more detailed guidance for performing area weighted calculations than is found in NFRC 100.

It is difficult to compare spandrel U-factor claims when each supplier uses a different evaluation size and methodology. Building designers rely on fenestration suppliers to provide spandrel U-factors, but NFRC 100 does not yet provide sufficient guidance to ensure that any two simulators will arrive at the same number.

- What is the intended use of the Reference Procedure?

This procedure was developed for the benefit of, and voluntary use by fenestration manufacturers and building designers. Project specifications can reference the "FENBC Reference Procedure" for the reporting of spandrel U-factors at both standard and project sizes.

U-factors simulated according to the Reference Procedure will be determined under a standard and publicly available set of conditions. It is hoped that this will give building designers greater confidence in the U-factors used for building energy models and tradeoff path calculations. The existence of a Reference Procedure will allow U-factors of products simulated under the reference conditions and sizes to be directly compared, ensuring greater transparency in the reporting of product performance claims.

- Why are there different spandrel reference sizes?

The standard reference sizes in NFRC 100 and CSA A440.2 do not reflect the most common spandrel conditions encountered in window wall products which typically have a narrower face height. Spandrels for window wall products are interrupted by floor slabs, a condition that NFRC 100 does not address.

- How does the Reference Procedure differ from NFRC 100?

The objective of the Reference Procedure differs from the objective of NFRC fenestration product simulations. The Reference Procedure limits itself to the concerns of building designers who require effective overall U-factors for opaque walls. The NFRC approach includes the determination of two additional properties that are significant for fenestration assemblies: Solar Heat Gain Coefficient and Condensation Resistance.

The Reference Procedure is based on NFRC 100, but provides two additional spandrel configurations in addition to the NFRC 100 Spandrel Panel model size. The Reference Procedure also provides additional guidance on matters known to influence spandrel performance and that are not currently addressed in NFRC 100.

NFRC recognizes the need for additional guidance, and while detailed guidance is not presently available, they have initiated a Spandrel Validation Task Group, of which RDH Building Science Inc. is a member. The Reference Procedure, User Guide and Calculation Tool have been shared with this Task Group.

Share this resource:

Design standards such as ASHRAE 90.1 and NECB require building designers to determine the effective U-factor of opaque wall assemblies clad with spandrel products. The Reference Procedure for Simulating Spandrel Panel U-Factors was created to allow spandrel U-factor performance claims to be objectively evaluated in a similar way as window U-factor performance claims that are based on NFRC 100 procedures.

Design standards such as ASHRAE 90.1 and NECB require building designers to determine the effective U-factor of opaque wall assemblies clad with spandrel products. The Reference Procedure for Simulating Spandrel Panel U-Factors was created to allow spandrel U-factor performance claims to be objectively evaluated in a similar way as window U-factor performance claims that are based on NFRC 100 procedures.